In 2020, the Tokyo Whisky & Spirits Competition added a division for shochu, Japan’s native spirit. In preparation for 2021’s Tokyo Whisky & Spirits Competition, let’s take a look at exactly how shochu differs from whisky, and what Japan can do to take the spirit to the next level on the global stage.

Text: Mamoru Tsuchiya

Photos: Mamoru Tsuchiya, Hiroshi Shibuya

Translation: Whiskey Richard

This article originally appeared in the Tokyo Whisky & Spirits Competition Official Guide Book 2020 (Shochu Division). It has been translated and posted here with permission.

For TWSC2020, 32 professionals in Western spirits and shochu came together to judge shochu. The ratio was about 2:1. Much of the vocabulary that’s obvious for shochu professionals is not heard often by Western spirits experts.What kinds of shochu are out there, and what are the standards? What is yellow koji, black koji, and white koji — none of which are found in Western spirits? Why are there multiple fermentations, a first and second? How is that fermentation done? What kinds of distillation methods are there, and why do wooden stills exist? What about maturation, clay pot maturation, and shochu’s absorbance regulations?

To answer those questions and more, TWSC Executive Committee Chair Mamoru Tsuchiya explains the differences between shochu and Western spirits, particularly whisky.

Defining Whisky and shochu

Worldwide, whisky is recognized as a distilled spirit made from grain and matured in wooden casks. Beer, despite being made from grain, is not whisky because it isn’t distilled. Gin and vodka are not whisky because they are generally not matured in wooden casks, though they too are distilled spirits made from grain. At a high level, whisky can be broken down by its raw ingredients and manufacturing method: malt whisky and grain whisky. For simplicity’s sake, this article will address the differences between malt whisky and honkaku (single-distilled) shochu and awamori.

There are two types of shochu: 1) single-distilled shochu (a.k.a. “honkaku” shochu and awamori. Formerly known as “otorui”) and 2) continuous-distilled shochu (“kourui”). Mixing the two is called konwa shochu. The parallel in whisky is malt whisky, grain whisky, and blended whisky.

Malting vs. Koji

The first major difference between single-distilled shochu (below, honkaku shochu) and malt whisky is saccharification of the grain (or potato, in honkaku shochu’s case). Whisky accomplishes this through malting of barley, while shochu uses koji-kin. Koji-kin is a type of mold. The academic name is Aspergillus oryzae, and it’s a fungus. Shochu takes advantage of the action of this koji-kin — creating enzymes — to saccharify the starch in the grain, yielding monosaccharides and disaccharides. In Western spirits like whisky and beer, this is instead accomplished via the enzymes produced during malting. This is the first major difference.

Koji-kin comes in yellow koji (used mostly in seishu), black koji, and white koji varieties. Depending on whether it’s grown on rice, barley, or potato, it’s referred to as rice-koji, barley-koji, or potato-koji. In malt whisky’s case, the malt is milled (into three components: husks, grits, and flour) then mixed with hot water in a container called a mash tun, where the saccharification happens. For shochu, rice-koji and barley-koji etc. are made by sprinkling koji on steamed rice or barley. This is called “seigiku,” a phase of production that’s today done using the triangular shelf method or drum method. In whisky, this is similar to using floor malting or drum malting.

Whisky uses unprocessed barley with its hull, while barley shochu uses pearled barley. The same is true of rice in shochu, which of course looks completely different from malted barley in whisky. The hull serves an important role in whisky, but in shochu, the koji won’t attach to the hulls.

Saccharification

During the saccharification phase in whisky, wort is created by adding hot water two or three times into the mash tun (saccharification tank). Wort is then extracted from the bottom of the container, passing through a filter called a lauter, which contains slits. There is no equivalent device or filter in shochu. Water is added to the koji as-is, then yeast is added, and the first fermentation begins. Which is to say that while the koji-kin is saccharifying, those sugars are simultaneously fermented into alcohol by the yeast. This process is unique to shochu and sake, and it’s referred to as multiple parallel fermentation.

That said, in malt whisky, the wort is not boiled before it’s moved to the fermentation phase, meaning the enzymes are still active. They deactivate if the temperature goes above 70°C. Even in the fermentation tank, the breakdown of the starches continues. From that perspective, whisky and shochu both use multiple parallel fermentation.

On to fermentation

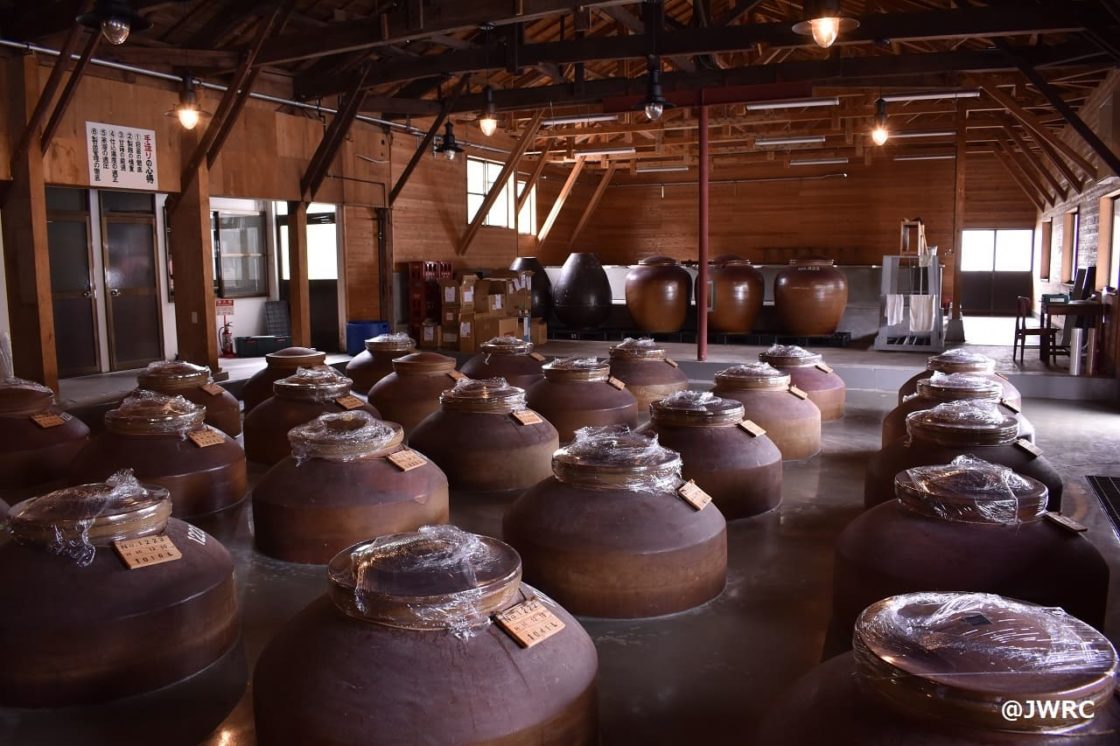

In malt whisky, fermentation happens in a fermentation tank called a washback. The material is typically stainless steel or wood. American pine is standard, such as Oregon pine and Douglas fir. In some cases, like the Chichibu Distillery in Japan, mizunara is used. Shochu’s first fermentation is about creating the yeast starter, and for its second fermentation it is moved to a larger container. It’s here that the main ingredient like rice, barley, potato, or kokuto sugar are added, creating shochu moromi (wash). After adding rice or barley, the volume ends up being about four or five times that of the first fermentation. That container is made out of stainless steel, enamel, or a traditional old-style earthenware pot. However there are no longer any kilns in Japan capable of firing such large pots, so most are made in China.

Most shochu distilleries don’t use the wooden fermentation tanks like you would find in whisky (though Miyazaki’s Osuzuyama Distillery does use a wooden fermentation tank for their second fermentation). For yeast there is only one species used by both whisky and shochu, its academic name Saccharomyces cerevisiae. Indeed there are yeasts specialized for making shochu, whisky, and wine on the market — with various shapes like pressed, liquid, and granule — and these are used. In recent years, experimentation with wine yeasts and beer yeasts has not been limited to just whisky and shochu.

Most shochu distilleries don’t use the wooden fermentation tanks like you would find in whisky (though Miyazaki’s Osuzuyama Distillery does use a wooden fermentation tank for their second fermentation). For yeast there is only one species used by both whisky and shochu, its academic name Saccharomyces cerevisiae. Indeed there are yeasts specialized for making shochu, whisky, and wine on the market — with various shapes like pressed, liquid, and granule — and these are used. In recent years, experimentation with wine yeasts and beer yeasts has not been limited to just whisky and shochu.

Shochu’s complex distillation system

The previous section described the raw ingredients, saccharification, and fermentation processes. The decisive difference between shochu and whisky is shochu’s usage of koji in saccharification of the starch in grain and potatoes, versus whisky’s saccharification via malting of barley, thereby activating enzymes in the starch to begin the process. Western spirits saccharify via the grains’ own strength, and Eastern spirits tap the strength of microorganisms for saccharification. You could say it’s a decisive difference between the civilizations.

Of course shochu and whisky are both spirits. Things are not over once the wash has been made: it must also be distilled. Let’s take a look at the differences between the distillations of the two spirits.

Malt whisky is batch distilled in a vessel called a pot still. Ordinarily it’s distilled twice, but some places do three distillations. Irish whiskey, for example, is traditionally distilled three times compared to the two distillations of Scotch. Pot stills are always made of copper. Stainless steel stills are never used in whisky. They are all handmade. Meaning no two are the exactly the same.

Honkaku shochu stills, on the other hand, are almost always stainless steel. There are some variations in shape like horizontal and vertical, but there is only a single distillation. However, wooden stills also exist. For a whisky expert, this seems very strange, but shochu’s direct heating makes this possible.

Heating the WASH and still

Whisky stills are heated one of two ways. The first is indirect heating via steam, and the second is direct heating via a fire lit underneath the pot. Think of the latter as a big pot on an open flame, or a kettle. In the past coal or peat was used as fuel for the fire, but in modern times, gas is used. Even so, this “direct fire distillation”–let’s call it direct heating, for simplicity–is still extremely rare. Most stills involve running pipes of steam through the still, heating the wash via steam. The pipes come in different types such as coil and pan, and external heating also exists, where the wash is removed from the still and heated externally. This system involves warming the wash via a heat exchanger (ala awamori’s horizontal stills). Regardless, none of the above involve mixing steam with the wash inside the still.

That’s in comparison to most shochus that use an entirely different system of direct heating, blowing steam into the wash itself. This ought to be dubbed “direct injection,” as the wash mixes directly with the steam. At this point the alcohol separates from the wash and rises to the top section inside the still. A stainless steel pipe installed inside acts as the exhaust for that steam. It’s easy to confuse these pipes with steam pipes in whisky, given they are called by the same name. But they serve a very different purpose. Shochu has indirect heating as well, but this is again something not found in whisky: a steam jacket is installed at the bottom of the pot, and the pot itself is heated.

The shochu parallel to whisky’s direct firing is called “jigamashiki,” where a fire is lit underneath the pot, heating the pot itself. While it’s the same as direct firing in whisky, in shochu, it’s only found in Awamori, specifically Ishigaki, Yonaguni, and other Yaeyama islands. To avoid burning the whisky, a rummager, with a copper chain, rotates inside the pot. In Ishigaki, during the initial stage of distillation, the wash is mixed with a stick!

LESS pressure

There’s something else found in shochu pot stills, but not malt whisky pot stills. The distinction between vacuum distillation and atmospheric distillation. For malt whisky, so long as the still is made from copper, decreasing the pressure inside the pot could lead to an implosion. This is only possible with strong stainless steel. At 1 atmosphere, alcohol vaporizes at 78.3°C (its boiling point). With lower pressure the boiling point also lowers. A vacuum still has a vacuum pump attached to it, allowing for the pressure inside the still to be lowered. This lowers the boiling point to around 30°C to 50°C, depending on the maker. Because the alcohol can be collected at a lower temperature, it ends up lighter, clearer, and more estery. That’s in contrast to atmospheric distillation, which yields heavy and rich distillate. Whisky only uses the latter.

There’s something else found in shochu pot stills, but not malt whisky pot stills. The distinction between vacuum distillation and atmospheric distillation. For malt whisky, so long as the still is made from copper, decreasing the pressure inside the pot could lead to an implosion. This is only possible with strong stainless steel. At 1 atmosphere, alcohol vaporizes at 78.3°C (its boiling point). With lower pressure the boiling point also lowers. A vacuum still has a vacuum pump attached to it, allowing for the pressure inside the still to be lowered. This lowers the boiling point to around 30°C to 50°C, depending on the maker. Because the alcohol can be collected at a lower temperature, it ends up lighter, clearer, and more estery. That’s in contrast to atmospheric distillation, which yields heavy and rich distillate. Whisky only uses the latter.

Overall, it becomes apparent that the distillation of shochu is far more complex than that of malt whisky, but the pivotal factor here is the material: copper. Copper is an excellent conductor of heat, it’s malleable, and importantly, copper acts as a catalyst to remove unwanted aromatic elements. Copper reacts to, and removes, unwanted aromas like rotten eggs. What happens in the case of shochu? From the whisky side of the fence, one has to wonder.

Oak casks used in whisky maturation

Let’s take a look at wooden cask maturation, a necessary condition for whisky. Without maturing in a wood cask, it can’t be called whisky. That’s what is required for Scotch, Irish, American, and Canadian whisk(e)y, as well as in EU law. The only whisky of the five major whiskies that doesn’t have an aging requirement is Japanese.

Scotch and American both require that wood to be oak. “Oak” is the common term for members of the Quercus genus within the beech family, and there are around 300 such members throughout the world. The common aspects are that they are deciduous, broadleaf, and produce acorns. This is often translated to “kashi” (live oak) in Japanese, but this term refers to evergreens. Oak, for our purposes, refers to the deciduous varieties (“nara”). In Japan, mizunara is essentially the only oak that can be used for casks. The two kinds of oak used in whisky are European oak (Quercus robur) and American white oak (Quercus alba).

In Scotch malt whisky, new casks are rarely used; over 90% are American white oak Bourbon casks. These are casks that have been used to mature Bourbon once. The remaining 10% are sherry casks that were once used to mature Spain’s fortified wine, sherry. Sherry casks are made from both American white oak and European oak. In any case, Scotch does not use non-oak casks. Using wood that is not oak is illegal. So what about shochu? Shochu does not have to be aged. In fact, it generally isn’t matured at all.

Many shochus mention aging in “kashitaru,” evergreen oak casks, but in actuality they are deciduous oak casks. Casks like Bourbon casks, wine casks, and Cognac casks are imported, but white oak wood is also imported to make new casks in Japan. In the past there were a handful of makers such as Maruesu Cooperage in Hanyu, Saitama, and Ariake Cooperage (Sangyo) in Miyazaki prefecture. Today only Ariake Sangyo remains.

Shochu can be stored and matured in oak casks and ceramic pots, but there is an important difference. Shochu has absorbance regulations, meaning that it can’t be bottled as-is with the amber color coming from the cask. A device called a spectrophotometer is used and the result must be A (absorbance) value of 0.08 or lower. A=0.08 for whisky is a super-light straw color. There are no official bottles with such a light color, and it’s only found in new pots aged less than a year. Scotch, Irish, and Canadian require at least three years of maturation, so there are no products on the market with such a light color. From a global perspective, this absorbance regulation is unheard of. But so long as that’s the directive of the National Tax Agency, it is what it is. It deprives shochu of the merits of cask aging.

Differing tax rates

The above discussed the differences in manufacture of shochu and whisky. Let’s also touch briefly on bottling and taxation. As mentioned earlier, there are two different kinds of shochu: single-distilled and continuous-distilled. These were previously known, respectively, as “shochu otorui” and “shochu kourui.” Honkaku shochu of course refers to the single-distilled variety. Upon bottling, only water can be added. It must be bottled at under 45% abv. For continuous-distilled shochu, it’s under 36% abv. The tax law book says “45% abv+ and 36% abv+ do not exist.” The maximum abv allowed to be called a shochu is thus 44% or 35%. Whisky, on the other hand, does not have a maximum bottling strength. Instead it has a minimum bottling strength, with Scotch, Irish, and American all requiring at least 40% abv.

Moving on to the tax rates. Japan’s liquor laws have both shochu and whisky categorized separately under “spirits,” with whisky being taxed such that anything 37% abv and under is 370,000 yen per kiloliter. It’s an extra 10,000 yen per abv percent above that, so a 40% abv whisky would be 370,000 yen + (3 x 10,000 yen), thus 400,000 yen per KL. It comes to roughly 280 yen per 700ml bottle. Anything bottled under 37% abv, be it 20% or 30%, is still charged the floor of 370,000 yen per KL. Let’s next look at shochu.

Shochu’s tax rate, for both single-distilled and continuous-distilled, begins at 20% abv. 1KL costs 200,000 yen, and like whisky, anything above that costs 10,000 yen per abv percent. So a 25% abv shochu pays 250,000 yen in tax per KL. Just looking at those numbers it appears to be the same tax rate as whisky, but whisky’s tax floor is 370,000 yen for 37% abv. Shochu’s tax floor is 200,000 yen for 20% abv, with finer granularity above that. This means that for anything bottled between 20% abv and 37% abv, shochu’s tax is lower than that of whisky. This is why the National Tax Agency has in the past said “shochu and whisky are taxed the same beyond 37% abv.” Put differently, shochu has a tax advantage over whisky when it is bottled between 20% abv and 37% abv.

That tax law is why many shochus are bottled at 25% abv or 30% abv, and why shochus above 45% abv do not exist.

Recommendations for globalization

It is this author’s opinion that while tax advantaged, for globalization of shochu, there is plenty of room for rethinking things like absorbance regulations and maximum bottling strength. Worldwide, research and expertise in wood cask aging is developing at a rapid pace.

Trends are shifting towards the importance of maturation, as well as concepts like single casks and cask strength. Single casks are whisky aged in only one cask; that flavor can never be completely reproduced. It’s a once-in-a-lifetime opportunity. Cask strength bottles add no water whatsoever, and are usually not chill-filtered.

Given this rarity and these kinds of value-adds, the time may have come to reconsider shochu from a global perspective.

Mamoru Tsuchiya is Japan’s foremost whisky critic. He is the Representative Director of the Japan Whisky Research Centre, and was named one of the “World’s Best Five Whisky Writers” by Highland Distillers in 1998. He served as the whisky historian for NHK’s Massan and he has published several books such as The Complete Guide to Single Malt Whisky, Taketsuru’s Life and Whisky, and The Literacy of Whisky. He is the editor of the bimonthly Whisky Galore, Japan’s only print whisky magazine.

2 Comments